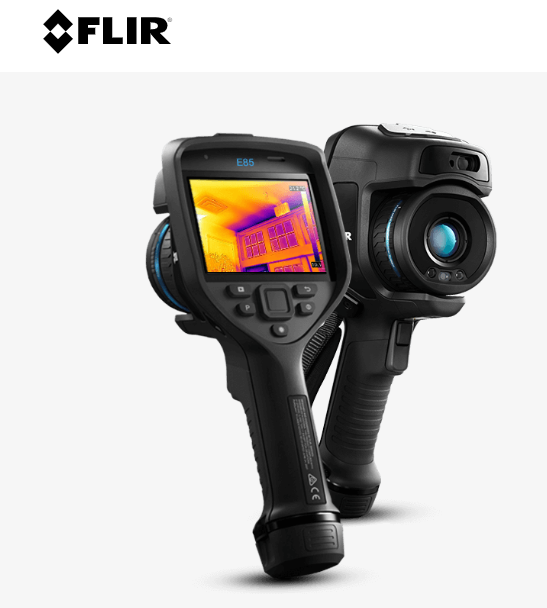

Our trained electrical personnel provide Non-Contact Infra-Red Thermal Images Services using Flir E85 advanced 384 x 288 with more than 110,000 point of Temperature for non-contact infrared thermal imaging services along with Flir Reports Professional formatting of Reports as a safe and reliable method of inspecting electrical systems and components of all shapes and sizes.

Non-contact thermal imaging can provide accurate feedback for maintenance purposes on a range of electrical systems, including both low voltage and high voltage installations.

Switchboard thermal surveys are a requirement when carrying out routine inspection and testing of electrical installations under the AS/NZS 3000:2018 Wiring Rules.

More and more business owners are required to provide thermal switchboard survey reports to insurance companies as part of their commercial premises fire risk assessment. In these cases, switchboard thermal survey reports are a valuable business document that can lower insurance premiums and help businesses save money.

Testing the integrity of your switchboard connections by checking for any excessive rise in temperature under normal operating conditions, our electricians will provide thermal imaging services that comply with the AS/NZS 3000:2018 Wiring Rules.

All electricians in the ALCHIMIE Electrical team will test, measure, and record results of the switchboard thermal survey in accordance with these Australian standards. When conducted by a licensed electrician, routine visual inspections can help your business to meet its responsibilities for safety, and even save on operating costs, by identifying potential faults before they become expense reactive maintenance repairs.

Following the completion of the site inspection, a report will be developed outlining the results.

Analysing the thermal images and creating a comprehensive inspection report that includes all results and recommendations is a key component of ALCHIMIE Electrical’s thermal imaging services.

Armed with comprehensive analysis information from the report provided, you’ll be able to clearly identify where potential problems are located. This will also allow you to mitigate risks with predictive, preventative, and planned maintenance, where required.

Thermal imaging makes use of powerful temperature analysis tools to check multiple spots, different areas, and to perform temperature difference measurement.

The use of thermal imaging services for maintenance purposes is by no means limited to large, high voltage applications. Thermal imaging can be used for inspections of electrical systems and components of all shapes and sizes.

Electrical cabinets and motor control centres are regularly scanned with thermal imaging maintenance services. If left unchecked, heat can rise to a point where connections melt and break down; as a result, fires may break out. In addition, loose connections in electrical systems suffer from load imbalances, corrosion, and increases in impedance to current.

Our trained electricians can use thermal imaging services to quickly identify hot spots, determine the severity of the problem, and help to establish the timeframe in which the equipment will need repairs.

Thermal imaging can be used to detect a range of failures in low voltage equipment, including:

These and other issues can be spotted at an early stage with thermal imaging maintenance. The detailed approach taken by our trained personnel will help you and your business prevent costly damages and avoid dangerous situations.

Heat is an important factor in high voltage installations. As electrical current passes through a resistive element, it generates heat, and over time the resistance of electrical connections will increase, due to loosening and corrosion, for instance.

The corresponding rise in temperature can cause components to fail, resulting in unplanned outages and even injuries. In addition, the energy spent on generating heat causes unnecessary energy losses. If left unchecked, the heat can cause connections to melt and break down, which may even result in fires breaking out.

Some examples of the types of failures in high voltage installations that can be detected with thermal imaging services:

These and other issues can be spotted at an early stage with a thermal imaging camera. A thermal imaging camera will help you to accurately locate the problem, determine the severity of the problem, and establish the timeframe in which the equipment should be repaired.

ALCHIMIE Electrical’s team can employ wireless technology to communicate to the non-contact infrared camera, assisting analysis and using the information gathered to determine balancing of electrical installations. This can also assist with maximum demand consideration, where other information is collected, including time of day, verification of tenancy, and services operating.

For more comprehensive maximum demand determination, it is recommended that power condition monitoring analyses services (including calculations) are provided as a separate option.

Our services can provide certainty that your facility maintains productivity up-time and efficiency, as well as saving you money with predictive and preventative maintenance.

If you would like to find out more about ALCHIMIE Electrical’s thermal imaging services, or any of our other condition monitoring and predictive maintenance services, then get in touch with the team today. Our highly trained and experienced electricians can answer your questions, and help you find more efficient ways to run and maintain the electrical systems and components in your business by detecting faults, or potential areas of concern before they can turn into costly problems.

Call us on 1300 735 822 to discuss how our people and systems can help you and your business.